Machines that move the world

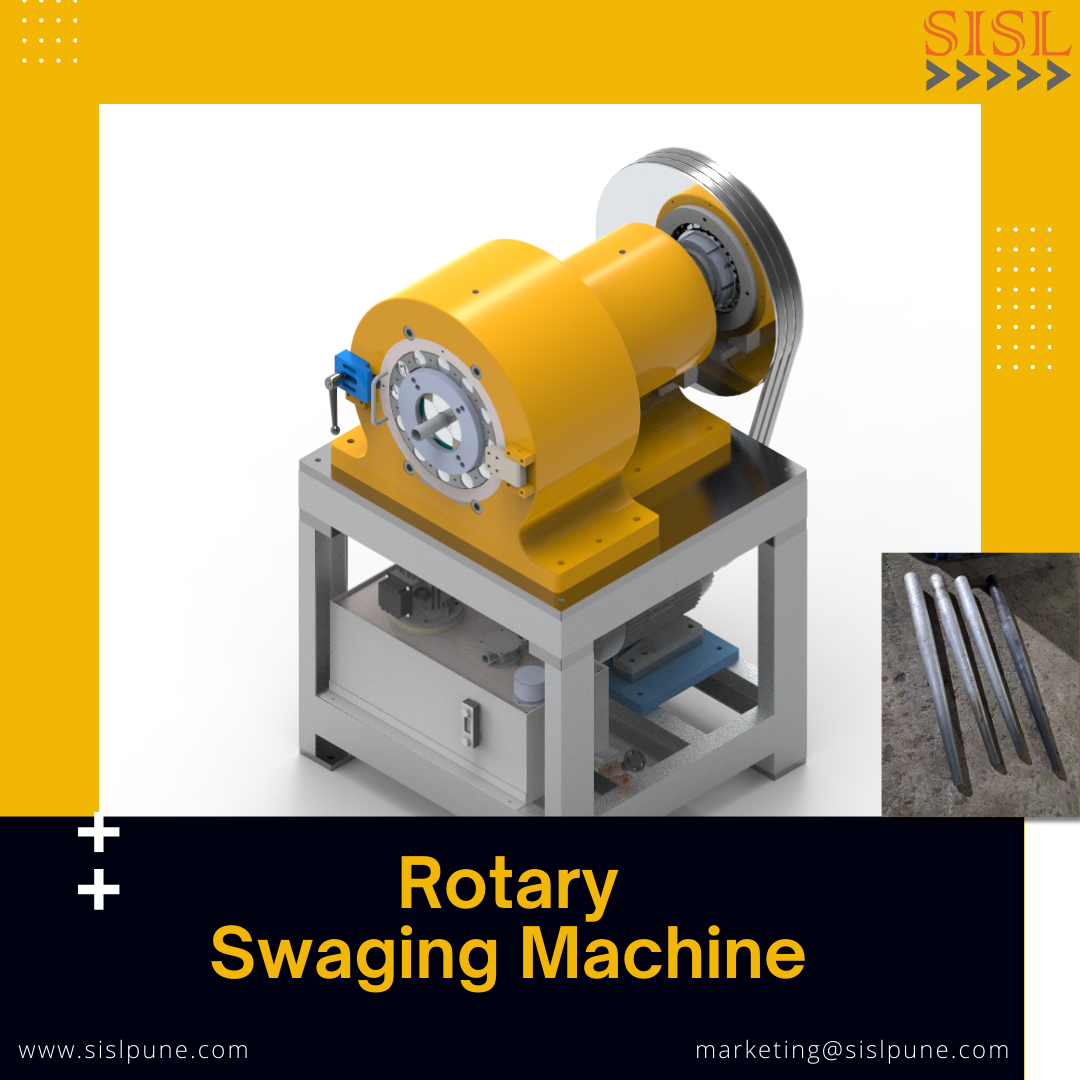

* Used for tapering of pipes and solids. Rotary swaging machines produce precise and complex metal parts with tight tolerances, meeting the stringent requirements of industries such as aerospace, automotive, and medical devices.

* Low-cost machine for cutting small length pipes. * Pipe diameter from Ø25 to Ø100 mm. * Pipe length accuracy achieved within ±0.3. * Hydraulic clamping ensures vibration free cuts.

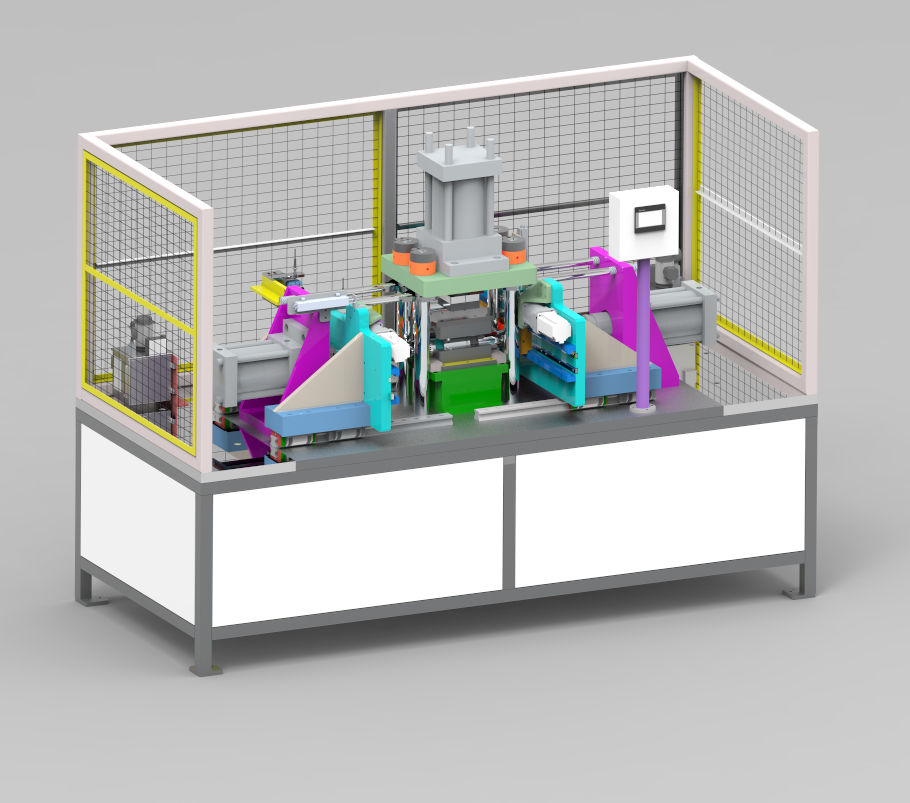

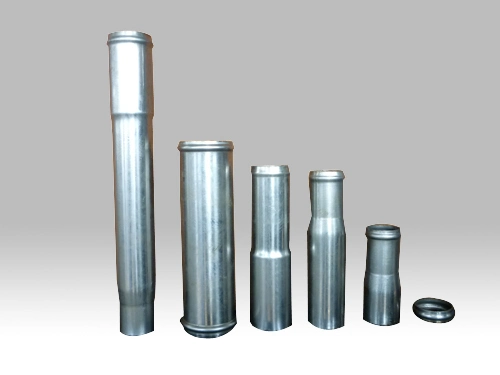

* This machine is designed to simultaneously Resize the ID and OD of the component. * Ovality generated due to welding operations on the shell can be corrected.

* A handle bar pipe cutting machine, or a pipe cold cutting machine, is used to cut pipes & tubes without generating heat or sparks, making it suitable for various materials & applications, including construction, & industrial settings.

* An aluminum section cutting machine is a specialized tool used in the metalworking industry for cutting aluminum profiles and sections into precise lengths.

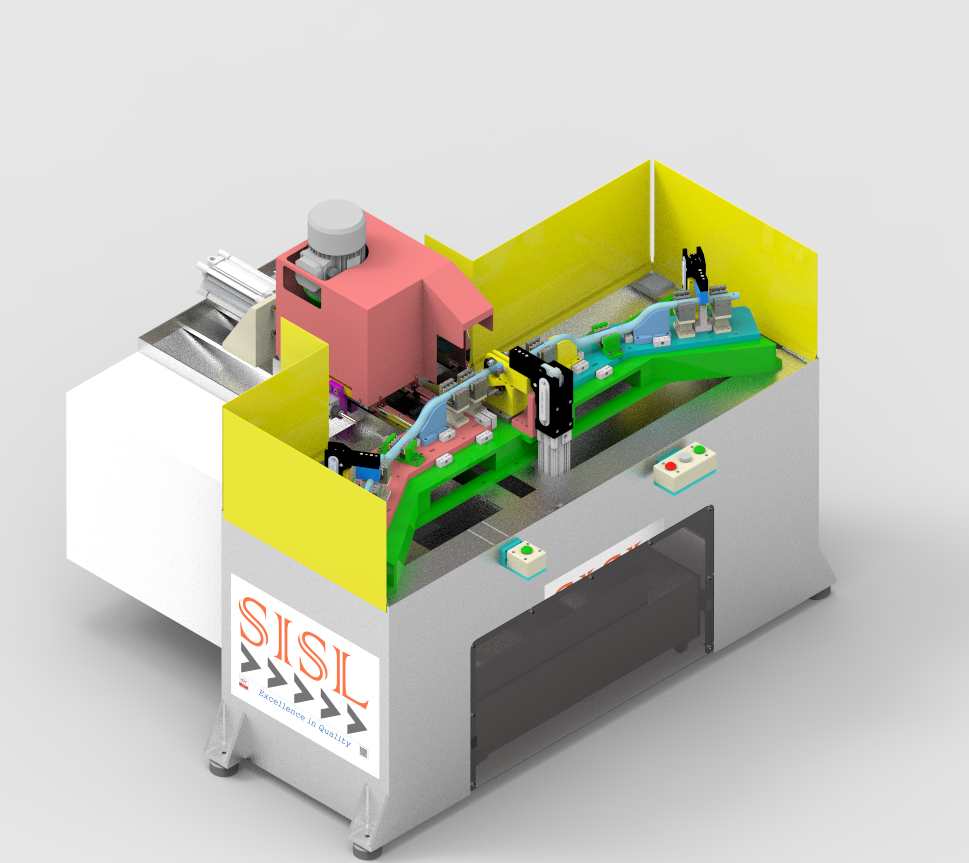

* This machine as designed to drill small diameter bend pipes With 100% acuracy and produce burr-free holes in a single operation. * Cycle Time: I second per drill. (Cycle time may vary according to drill size and raw material.)

* This machine as designed to drill small diameter bend pipes With 100% acuracy and produce burr-free holes in a single operation. * Cycle Time: I second per drill. (Cycle time may vary according to drill size and raw material.)

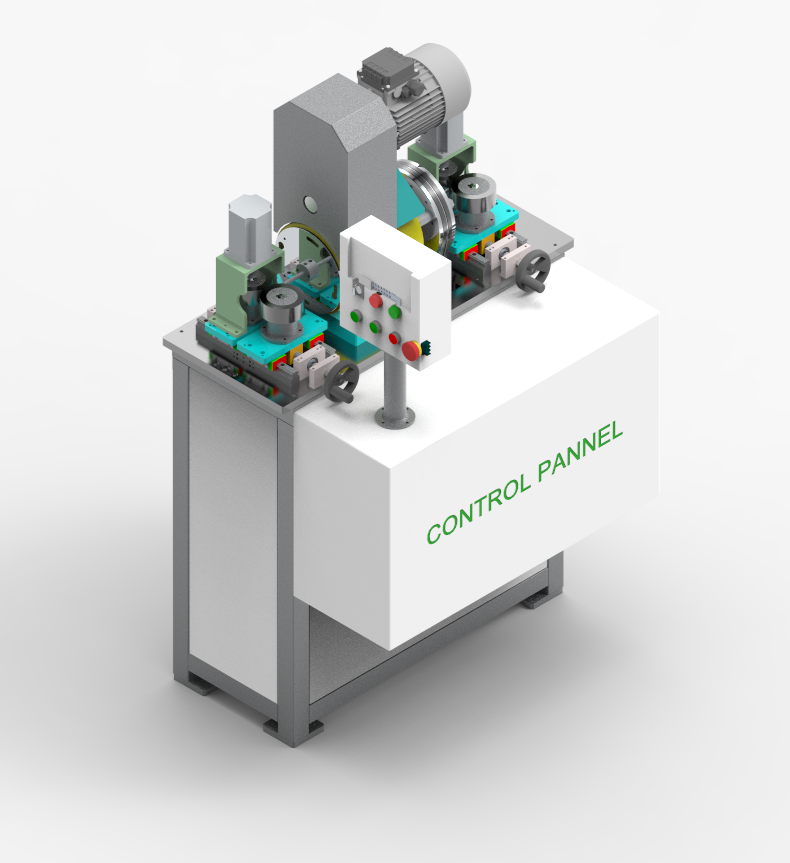

* A segmented swaging machine is a type of equipment used in metal forming processes, designed to reduce or shape the diameter of rods, tubes, or wires. The term "segmented" refers to the machine's use of multiple die segments that surround the workpiece.

* Used for tapering of pipes and solids. Rotary swaging machines produce precise and complex metal parts with tight tolerances, meeting the stringent requirements of industries such as aerospace, automotive, and medical devices.

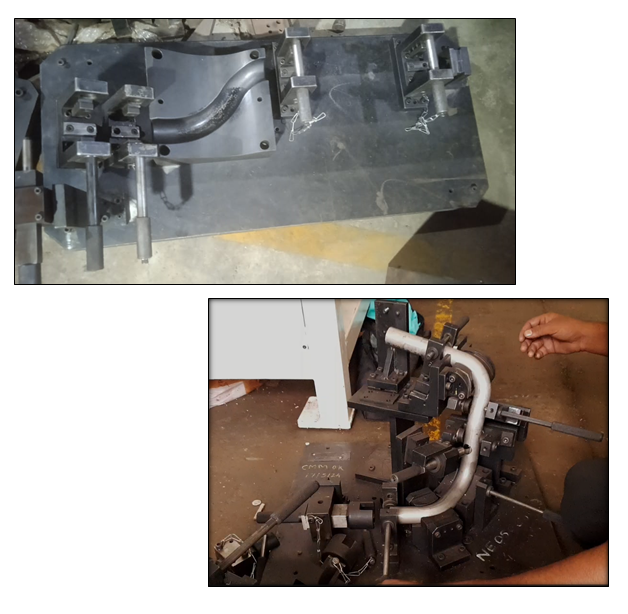

* Bend checking fixtures are specially designed to inspect

the bends on Solid rods and wire forms . This fixture

can check multiple bend points.

* We have manufactured fixtures from 2.5 mm dia wire

to 18 mm complex form solid.

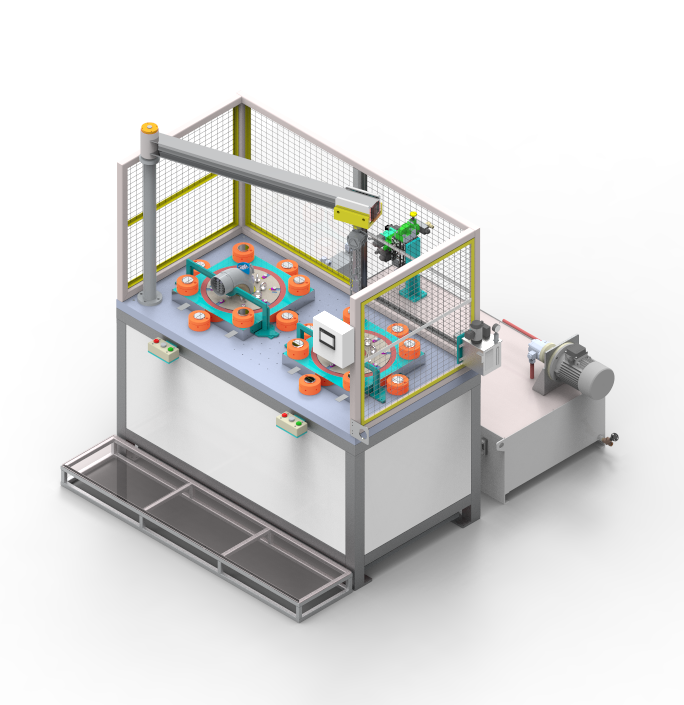

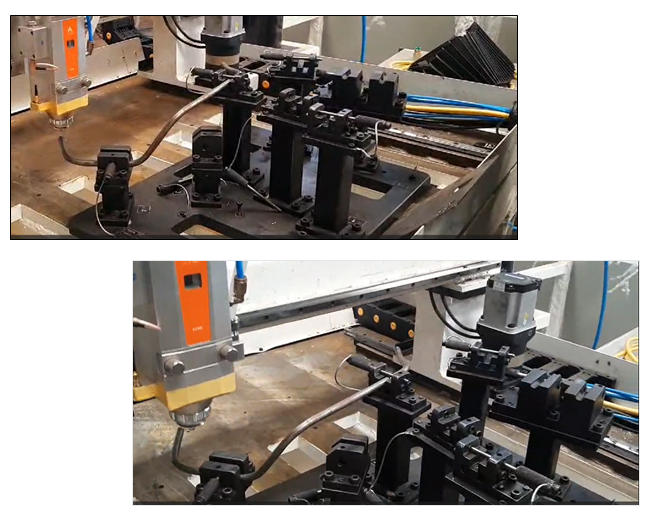

* The machine fixtures are designed for the SISL Laser Drilling SPM. This fixture is capable of clamping 4 bent pipes at the same time for the drilling operation.

* It is designed for checking of bend pipes this fixture consists of elements for pipe position checking in the straight portion even with complex bend angles, also it features bend profile templates at bend radius for complete profile checking of pipe.

* A handle bar pipe cutting machine, or a pipe cold cutting machine, is used to cut pipes and tubes without generating heat or sparks, making it suitable for various materials and applications, including construction, utilities, and industrial settings.

* An aluminum section cutting machine is a specialized tool used in the metalworking industry for cutting aluminum profiles and sections into precise lengths.

* This machine as designed to drill small diameter bend pipes With 100% acuracy and produce burr-free holes in a single operation. * Cycle Time: I second per drill. (Cycle time may vary according to drill size and raw material.)