SPECIAL PURPOSE MACHINES

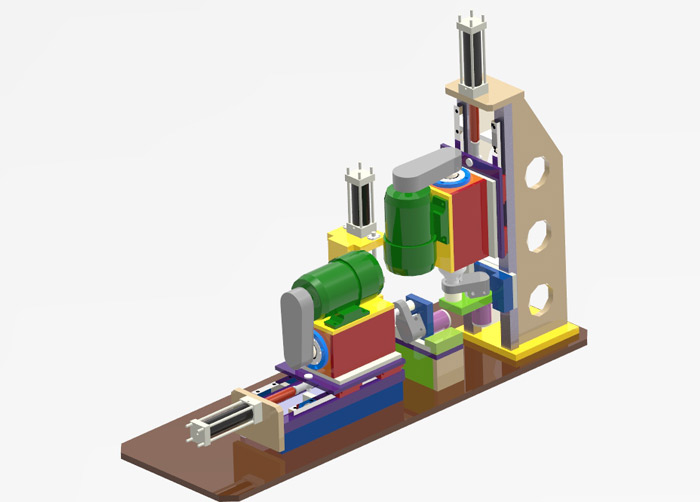

MULTI SPINDLE DRILLING MACHINES

- This Machine is designed for drilling more than 1 holes in pipe at given CD with given accuracy with the help of multiple number of motors

- Hydraulic dampers are attached to control drilling feed accurately

- Automatic Start - Stop of spindle motor through pressure switch

- Reduces production time

- Clamping attained by pneumatic cylinders strategically placed below work-table

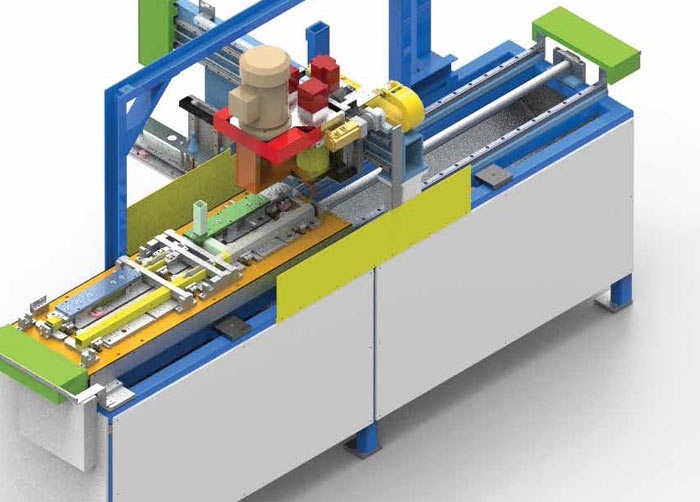

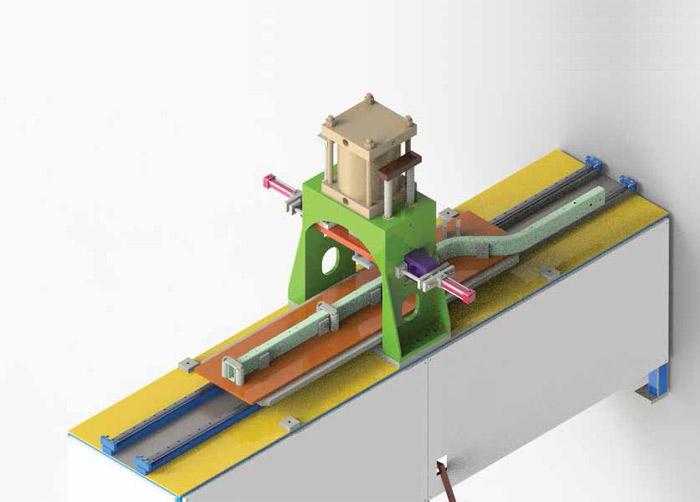

LINEAR DRILLING MACHINES

- Designed for various drill sizes and tube lengths

- Processes 2 jobs at a time

- For drilling in Square Tubes as well as Round tubes

- This machine is designed for Square tubes used in chassis building

- Drilling motor speed is automatically selected depending on Tube and Drill dimensions

- Self-centralizing Clamping System

FINE BORING MACHINE

- This machine is used for fine boring of auto components normally welded sheet metal assemblies where high accuracy is required after welding

- This machine consists of two boring heads in front of each other which are driven by separate induction Motors

- Feed of head achieved through hydraulic cylinders with micro adjustment

- Inbuilt Automatic self-lubrication system

- Proper clamping of component is attained through highly rigid hydraulic clamps

DOUBLE HEAD DRILLING MACHINE

- Used for welded sheet metal component

- Two heads facing each other are used to attain concentricity in hole

- Pneumatic cylinders used for quick rapid feed

- Drilling Feeds are controlled through hydraulic speed control unit

- Cycle time as low as 30 second

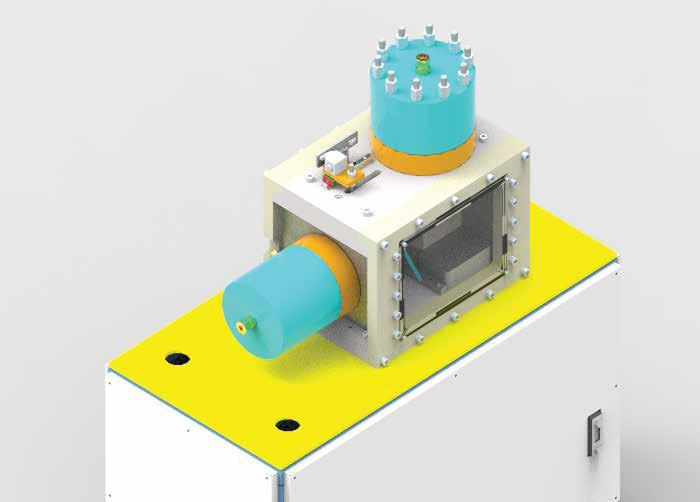

COLD FORMING MACHINE / COLD FORGING MACHINE

- Used for forming of rods as well as pipes.

- Steel Rods up to Ø 12 mm and pipes up to Ø 30 mm can be forged.

- Special quick change-over dies made up of high rigidity tool steel materials.

- Repeatability of machine is ensured to 50 µ

- Cycle time of 10 sec can be achieved for forging the component

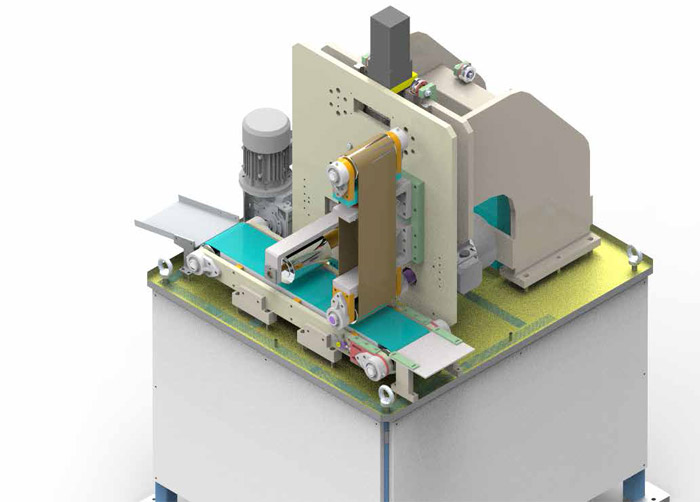

DEBURRING MACHINE

- Deburring operation is very important on any component

- We manufacture deburring machines s pe requirements e.g. Deburring machine for a specific component / Gear deburring machine

NAIL PIERCING MACHINE

- We are offering a comprehensive range of Nail Spotting Machine which is a special designed nail spotting machine used for manufacturing various types of discharge electrodes.

- These are widely known for its special features such as sturdy construction, high performance, user-friendly operation, longer service life and cost effectiveness.

- this machine is high in demand in diverse industries.

FLOW DRILLING MACHINE

- Flow drilling is method of making holes in which material is pushed out of the way with the aid of heat from friction.

- It is also known as Friction Drilling